What’s New? What’s Old?

“Is this part of the original house?” is one of the questions people ask when they visit Midori Haus. We feel complimented when people ask that question because we did put fair amount of effort into re-using materials to give it the look and feel of a vintage house that was originally built in 1922. When we didn’t have any specific old looking items to re-use we bought new items that were made to look in the old style.

An example of this is the push button switch for the lights. The house did not have push button switches when we bought it in 2010 but we are pretty sure that the orignal house did. So to give it the original look we bought push button switches and switch plates in oil-rubbed bronze finish from Rejuvenation in Berkeley.

Most are simple on/off switches where you press the top button to turn lights on. To turn the lights off you press the bottom button. Some of the switches have a dimming function where you press the bottom button for on/off and the top is an adjustable dial to control the light intensity. We chose to use these antique looking switches for pure decorative purposes. There are no energy efficiency advantages.

Let’s look at the hallway bathroom door for a good mixture of old and new items. The frosted glass on white door with the glass door knob has a vintage look. When friends saw this door before the renovation they would say, “That looks like the door in my grandmother’s old house,” or “My basement door in my old bungalow has a door just like that.”

We added the stained glass window above the door to let more light into the hallway. People often perceive this to old but we got this new from The Bright Spot.

We added the stained glass window above the door to let more light into the hallway. People often perceive this to old but we got this new from The Bright Spot.

The door, the knob and the trims are original with fresh paint.

We kept the built-in storage unit in the hallway. These front got some fresh paint and the inside was simply cleaned. It smells of old wood when you open the drawers and it’s part of the charm.

Most of the floor is original. We removed the floor coverings (tile, carpet, linoleum) and had the original wood floors refinished.

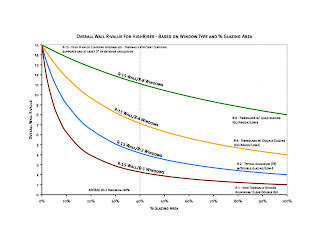

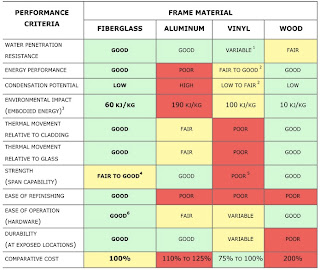

The windows on the front of the house retained the same positions and size. The triple-pane, Argon-filled fiberglass windows have a much better performance than the old single pane leaded window.

We did re-use the trims around the windows. Santa Cruz Green Builders did a great job of matching the wood covering the deep window sill with the original window trims.

Notice the patched marks of nail holes on the window trim. This is evidence of prior homeowners installing curtain rods multiple times on this window trim.

The mudroom bench and cabinets are new. This practical set of built-in furniture was made by Loughridge Cabinets in Scotts Valley. When you walk into the mudroom/kitchen area from the side door you can park your groceries on the bench, hang your hat and coat on the hook, and sit on the bench to take your shoes off.

The mudroom bench and cabinets are new. This practical set of built-in furniture was made by Loughridge Cabinets in Scotts Valley. When you walk into the mudroom/kitchen area from the side door you can park your groceries on the bench, hang your hat and coat on the hook, and sit on the bench to take your shoes off.

Speaking of the mudroom, we did use a piece of the old mudroom in our new kitchen. The breadboard on the wall was re-used on the breakfast bar in the kitchen.

In our old kitchen the gas water heater was next to the stove, strapped onto the wall. The gas stove and the water heater shared a flue going up through the ceiling to exhaust above the roof.

As you enter the front door you’ll see this tidy shoes storage to your right. We ask all visitors to take their shoes off in our house and this is one of the places where you can store them.

Also made by Loughridge Cabinets, the concept of the Japanese “getabako” is expressed in the arts and crafts style.This is built back into the wall and protrudes through the dining room. In the dining room the back side of the shoes storage cabinet looks like a nice stand.

The buffet is the original built-in furniture that stayed in place during construction. It was covered up for 13 months while the crew worked around it.

French door between the dining room and kitchen is also original piece of the house.

Finally, I added a touch of Japanese influence in this arts and crafts house by re-using my other’s old kimono as cushion covers.